You can find detailed information about vacuum chamber design and production on our other website.

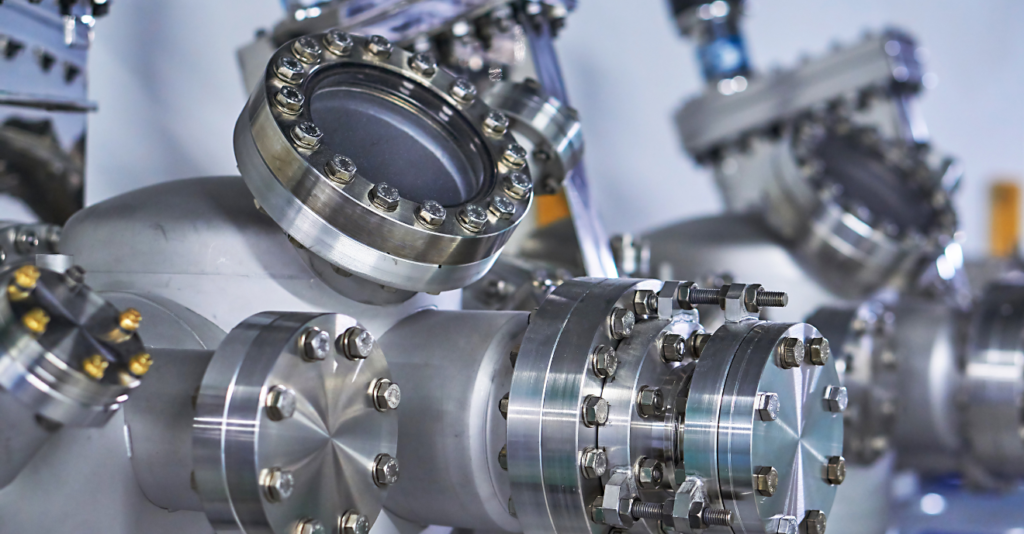

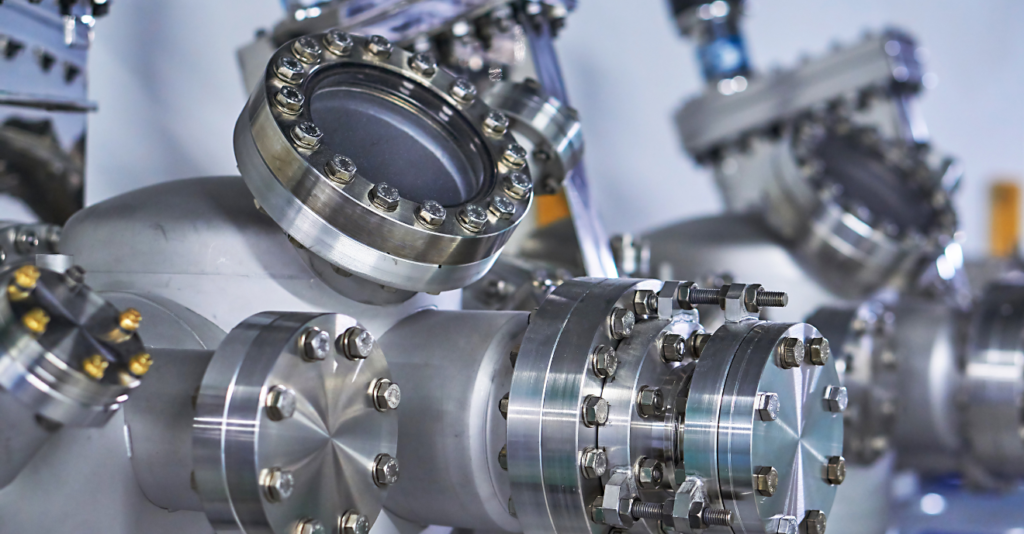

Vacuum chambers are used in a variety of applications, including scientific research, industrial processes, and the production of electronic devices.

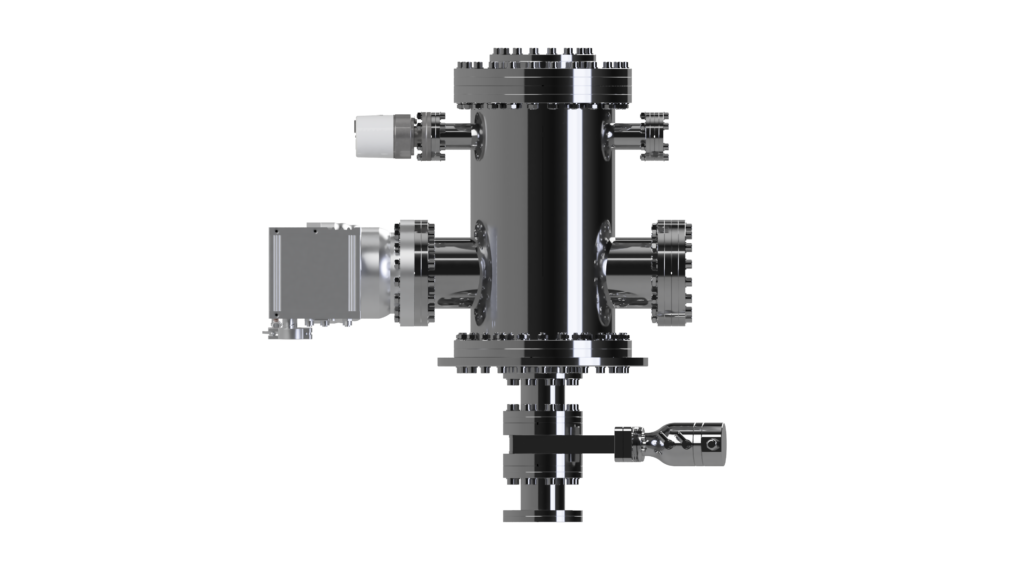

In order to design a vacuum chamber, engineers must consider factors such as the size and shape of the chamber, the materials used to construct it, the type of vacuum pump to be used, and the intended use of the chamber.

- Identification of customer needs.

- Customized product design.

- Vacuum pump selection.

- Customer approval.

- Production, control and testing.

In a high vacuum, the pressure of the gas is much lower than atmospheric pressure, typically less than 10^-5 pascal. This can be achieved through the use of a vacuum pump to remove the air from a sealed chamber. High vacuum is used in a variety of applications, including scientific research, industrial processes, and the production of electronic devices. It allows for the creation of a clean and controlled environment in which certain phenomena can be studied or processes can be carried out without interference from air or other gases.

When designing a vacuum chamber, engineers must consider a number of factors to ensure that the chamber will be effective and suitable for its intended use. Some of the key considerations include the following:

Size and shape: The size and shape of the vacuum chamber will depend on the intended use of the chamber and the equipment that will be placed inside it. For example, a chamber used for scientific research may need to be large enough to accommodate a variety of experiments, while a chamber used in industrial processes may need to be compact and easy to integrate into a production line.

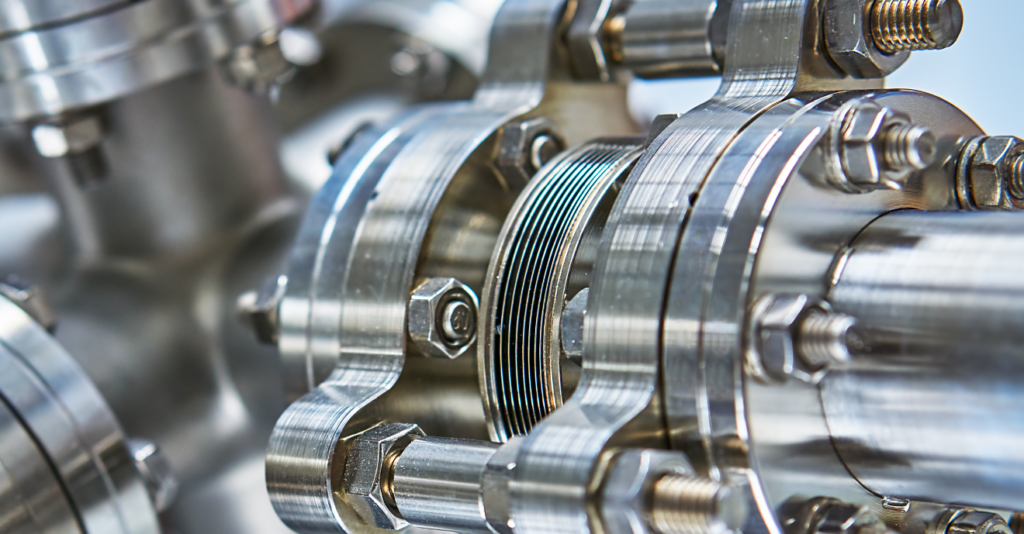

Materials: The materials used to construct the vacuum chamber must be able to withstand the vacuum environment and the temperatures and pressures that may be encountered during use. Common materials used in vacuum chamber construction include stainless steel, aluminum, and various alloys.

Vacuum pump: The type of vacuum pump to be used will depend on the desired level of vacuum and the size of the chamber. Different types of vacuum pumps, such as mechanical pumps, turbomolecular pumps, and cryogenic pumps, are suitable for different applications and have different capabilities.

Intended use: The intended use of the vacuum chamber will influence many of the design decisions, such as the size and shape of the chamber, the materials used, and the type of vacuum pump. For example, a vacuum chamber used for space simulation will have different requirements than one used for electron beam welding.

Safety: Vacuum chambers can pose safety hazards, such as the risk of implosion or exposure to high levels of radiation. Careful design and testing are necessary to ensure the safety of the operators and the equipment inside the chamber.