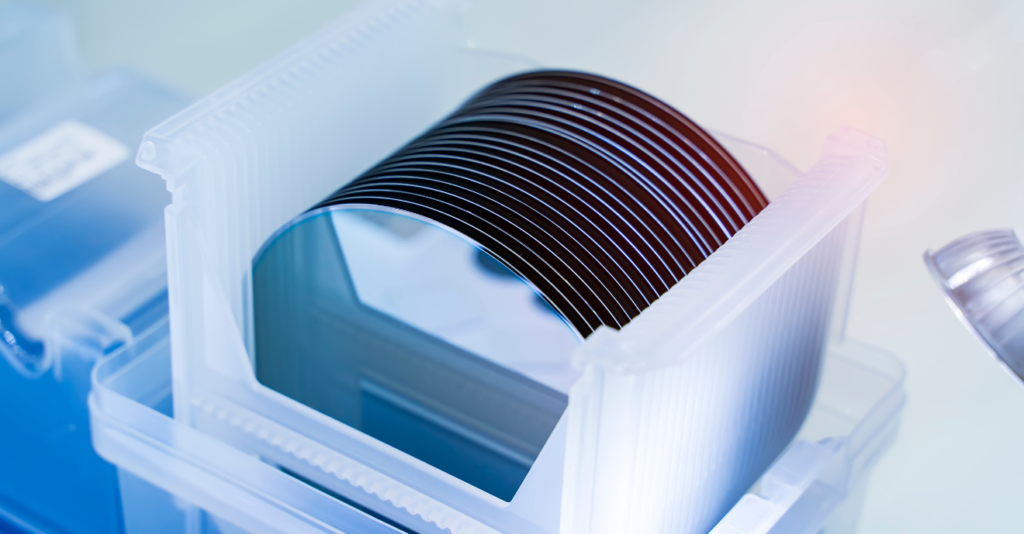

Quartz, also known as silicon dioxide (SiO2), is a naturally occurring mineral that is commonly used as a substrate in a variety of applications. In the context of electronics, a substrate is a material on which other components, such as microchips or thin film layers, are deposited or fabricated.

Quartz has a number of properties that make it an attractive substrate material, including high thermal stability, chemical resistance, and good electrical insulation. It is also extremely hard and has a high melting point, making it resistant to damage and wear.

The specific specifications of a quartz substrate may vary depending on the intended application and the specific requirements of the device or system in which it will be used. Some common specifications that may be considered when selecting a quartz substrate include:

- Thickness: The thickness of a quartz substrate can range from a few micrometers to several millimeters, depending on the application.

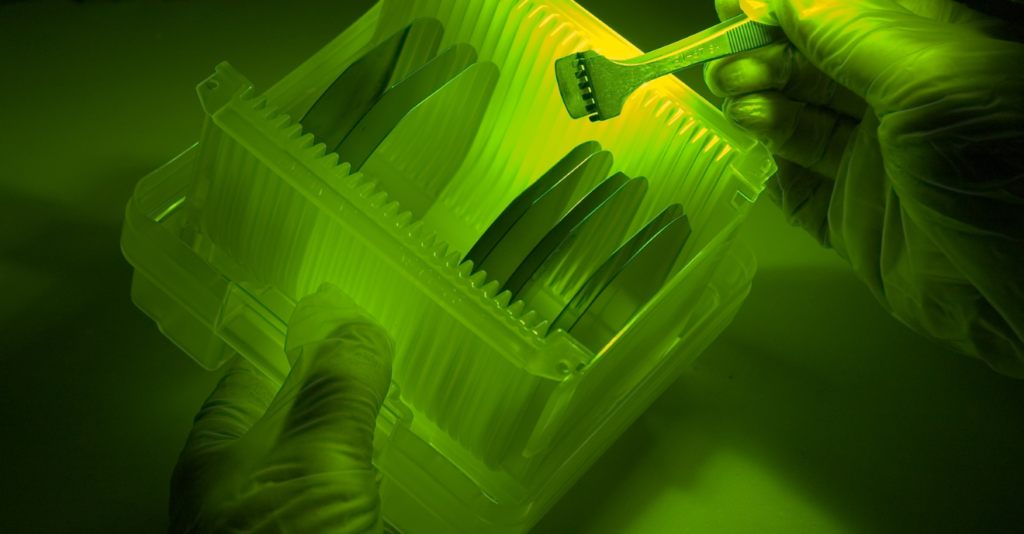

- Surface finish: The surface finish of a quartz substrate can be important for certain applications, such as those requiring a smooth, polished surface for thin film deposition or for making precise optical measurements.

- Dimensional tolerance: The dimensional tolerance of a quartz substrate refers to the allowable deviation from the specified dimensions of the substrate. This can be important for applications where precise dimensions are required, such as in the production of MEMS devices.

- Thermal expansion coefficient: The thermal expansion coefficient of a quartz substrate refers to the change in the substrate’s dimensions in response to changes in temperature. This can be important for applications where the substrate will be exposed to a wide range of temperatures, as it can affect the dimensional stability of the device or system.

- Chemical resistance: Quartz is generally resistant to a wide range of chemicals, but the specific level of resistance may vary depending on the type of quartz and the conditions to which it is exposed.

- Electrical properties: The electrical properties of a quartz substrate, such as its dielectric constant and breakdown voltage, can be important for certain applications, such as in the production of capacitors or other electrical components

Quartz substrates are commonly used in the production of microelectromechanical systems (MEMS), as well as in the fabrication of thin film layers for photovoltaic cells, sensors, and other electronic devices. They are also used in the production of quartz crystal resonators, which are used to maintain precise frequency standards in a variety of applications, including telecommunications and timekeeping.

Contact for Details